HOW IT WORKS

The patent pending Ergaspira200 has a 200 µL ± 10% draw volume and a 100 ± 10% µL blowout volume, which in combination allow complete volumetric emptying of the typical working volume of a 96-well plate.

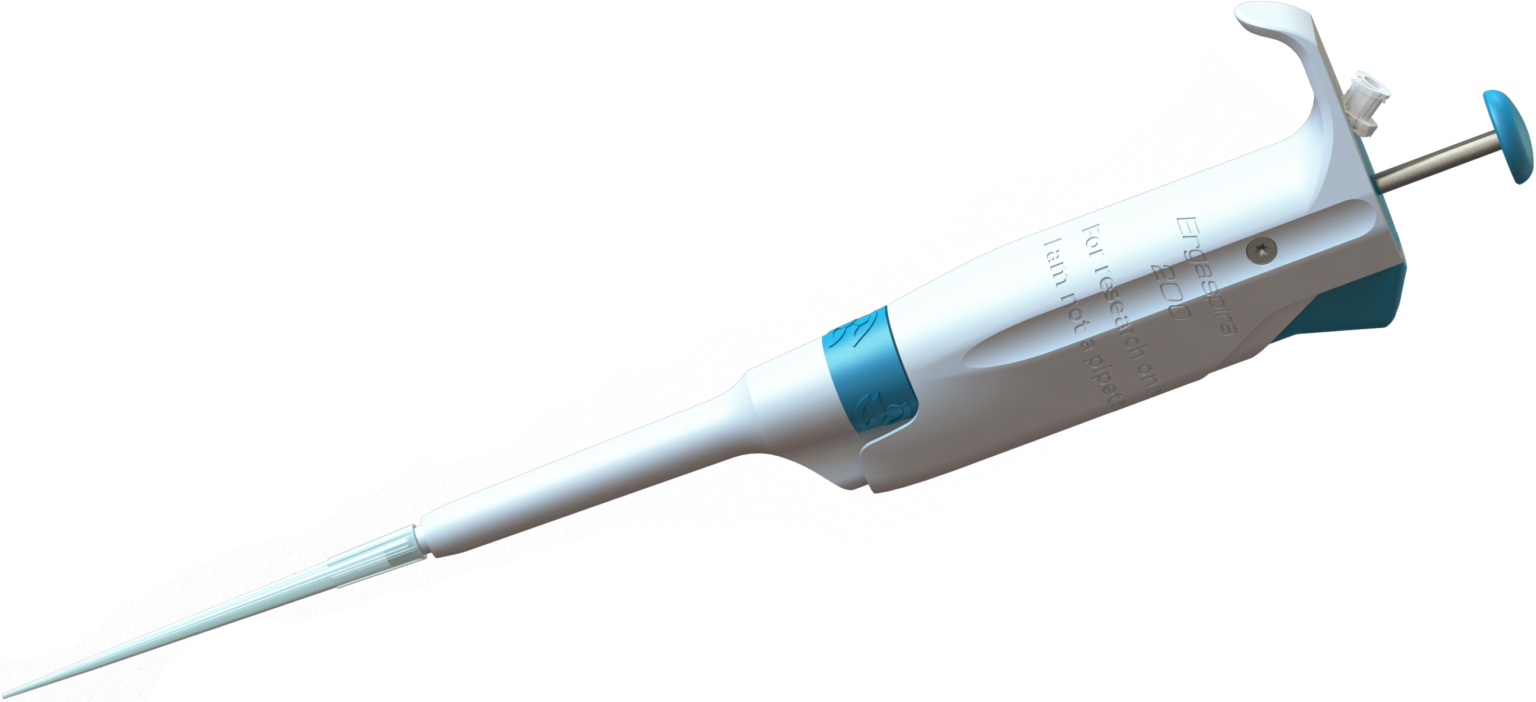

The icepick-like form factor of the micropipette may not be the most ergonomic one around but it has formed the basis for countless ingrained and subconscious movement patterns that minimize sweeping arm motions, open and close containers, draw liquid, and eject tips. That is why the familiarity of the outer shell of the Ergaspira200 to a micropipette is not a coincidence but a design requirement.

The Essentials

The Ergaspira200 does not contain electronics and can be autoclaved at 121°C for 20 minutes.

There are just two control points on the tool:

- The plunger button

This button operates the air displacement mechanism that provides the pipetting function. The button has three distinct and tactile stops: At the rest position, the air displacement mechanism is fully retracted, the first stop at 200 µL and the second at 300 µL.

- The tip ejector button

This button operates the tip ejector AND the internal vacuum aspiration valve. At the rest position, the valve is closed. Pressing down on the button will gradually open the valve to reach a fully open position as the tip ejector contacts the pipette tip. Pressing further will close off vacuum and eject the tip.

On the top of the tool, there is one female Luer-Lock tube connector for convenient detachment from the vacuum waste bottle.

If intermittently put down on a bench face, the large flat face of handle shell combined with the handle’s center of gravity forces the tip and shaft to remain horizontal to prevent drip.

Materials of the shell and the liquid path

The Ergaspira200 shell is made from 3D printed polybutylene terephthalate (PBT), which is the most common micropipette handle material. The wetted materials in the Ergaspira200 liquid path are:

- Polypropylene (PP) P200 tip (3rd party item)

- PP tip holder

- 316L stainless steel tube, peroxide cured silicone O-ring

- Peroxide cured silicone tubing

- PP Luer-lock adapter (3rd party item)

The thermal and chemical resistance of this materials palette is fully compatible with liquid handling in biomedical labs.

No fluoropolymers

Traditionally, micropipettes and vacuum aspirators have tip holders and seals made from fluoropolymers such as PVDF and FKM, respectively. These materials have outstanding mechanical, chemical, and thermal properties, but are environmentally and societally highly problematic materials throughout their lifecycles. As a startup with a clean slate, Ergasta have deliberately chosen to substitute PVDF with polypropylene and FKM with silicone. The potential decrease in parts longevity will be compensated by our expanded customer service.

So, how does it work?

The familiar shell of the Ergaspira200 hides two innovations:

- A low-force, single-component, normally-closed valve

- A translatable air displacing conduit.

The valve, which is operated by the ejector button, opens the aspiration line with a high degree of modulation. When the valve is closed, the steel tube and a part of the silicone tubing become air displacing body that slides in and out of the tip holder – just like in a micropipette.

The air displacement mechanism is fully integrated into the liquid path and can be cleaned by aspirating isopropyl alcohol, hydrogen peroxide disinfectant etc.

The liquid path from the steel tube to the Luer-lock adapter exiting the handle is one uninterrupted length of silicone tubing. In other words, there are only three internal transitions in the liquid path, which increases, reliability, leak resistance and reparability.

Who even comes up with this?

In short: We do!

There are several more ingenuities hidden in the design, if you are interested in knowing the details and background feel free to send your comments and questions to dang@ergasta.com

Supported by